Automotive Body Sheet Program

Aleris Rolled Products, Inc. is a global leader in the production of rolled, extruded and recycled aluminum as well as specification alloys. Headquartered in Cleveland, Ohio, Aleris has more than 40 production facilities throughout Europe, America and Asia.

The upcoming stringent car fuel emissions standards in North America will induce a market transfer from steel to aluminum products. Experts estimate a substantial rise in market demand for aluminum.

In order to cover this increasing market demand, Aleris has set up an aluminum Automotive Body Sheet (ABS) program in North America. The ABS program consists of the implementation of an ABS-plant and innovation center based on the experience gathered in Duffel, Belgium where Aleris has been producing automotive products for over ten years.

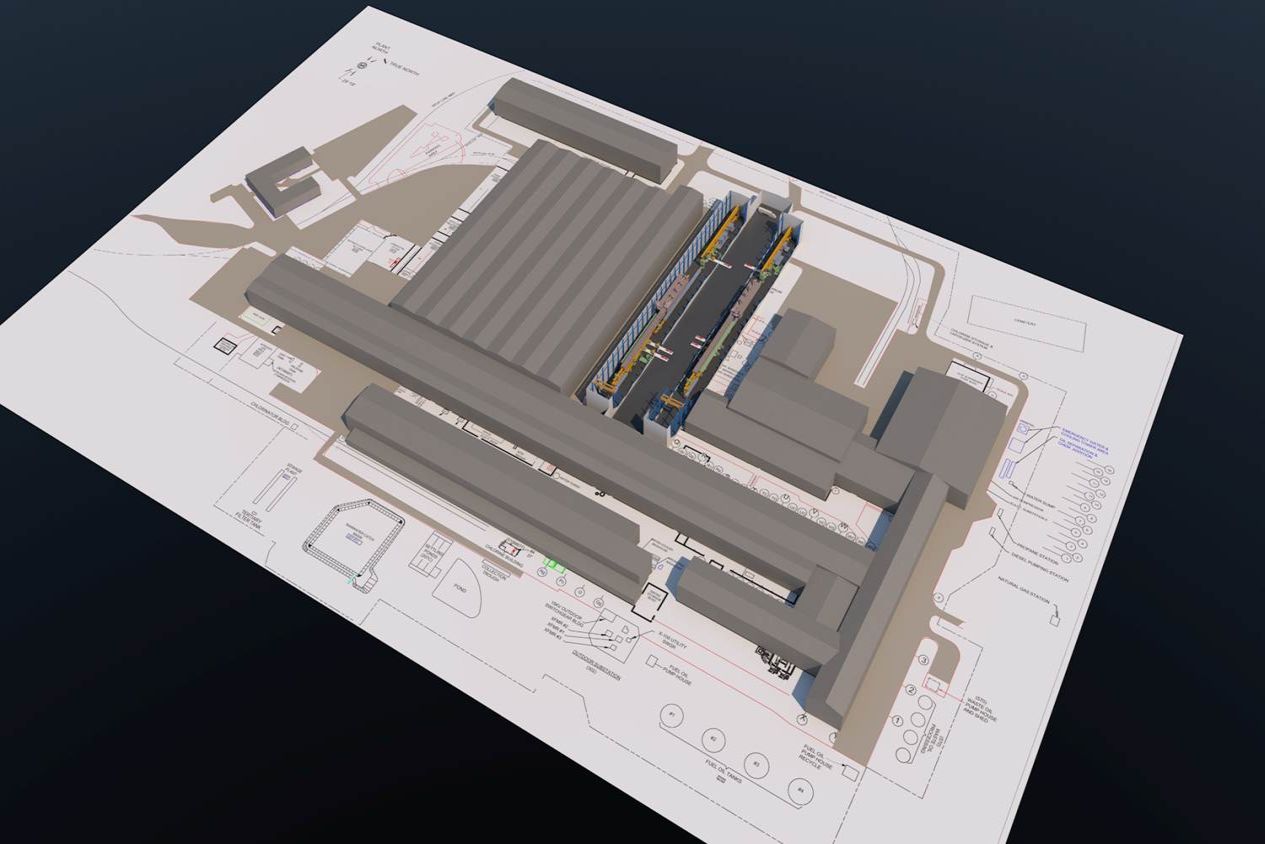

The new ABS-plant will be constructed in an existing Aleris production facility, Lewisport, KY.

The Lewisport factory integrates multiple aluminum process steps including casthouse, hot rolling mill, cold rolling mill, annealing furnaces, painting lines and packaging lines.

To reach quality requirements of the automotive industry, Lewisport will receive a state-of-the-art cold rolling mill and two Continous Annealing Lines with Pretreament functionality (CALP).

The new equipment will be situated in the heart of the factory, allowing for a very efficient logistical operation.

Principal project data

Implementation of Automotive Body Sheet - plant North America .

Budget: 340 M US $.

Scope IPS

Strategic Consulting

- Project Risk Analysis

- Plant Master plan

Project Feasibility

- Process Description

- Logistical concept

- Overall Time Schedule

- Preliminary Budget

Project Preparation

- Project Definition File

- Permitting Roadmap

- Procurement

Project Realisation

- Project Coordination

- Engineering Review

IPS operational unit(s)

- IPS Belgium sa

- IPS USA Corp.